In the realm of power transmission and communication, both Optical Ground Wire (OPGW) and All-Dielectric Self-Supporting (ADSS) cables play crucial roles. While they share the common function of integrating optical fibers for data transmission, they are designed differently and have distinct applications. In this article, we will explore the eight key points that highlight the differences between OPGW and ADSS cables.

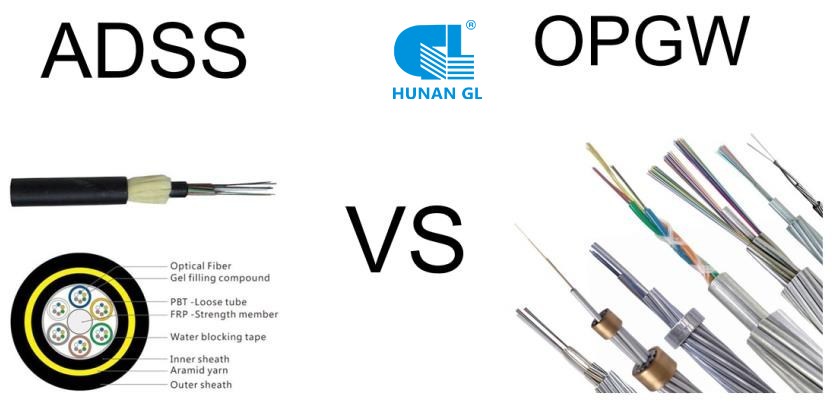

- Construction and Design:

- OPGW Cable: OPGW cables consist of a central aluminum pipe that acts as a conductor for electrical power transmission. The optical fibers are placed inside this pipe and surrounded by layers of steel and aluminum wires for mechanical strength and protection.

- ADSS Cable: ADSS cables, on the other hand, are made entirely of dielectric (non-metallic) materials. The optical fibers are integrated into the core of the cable, which is composed of high-strength aramid fibers and a protective outer sheath.

- Electrical Conductivity:

- OPGW Cable: OPGW cables have a conductive metal (aluminum) core, allowing them to be used as overhead ground wires in power transmission systems. This feature provides a path for fault current during electrical faults, protecting the transmission line.

- ADSS Cable: ADSS cables are non-conductive since they do not contain any metal components. As a result, they cannot be used as ground wires and are primarily dedicated to providing communication capabilities.

- Mechanical Strength:

- OPGW Cable: Due to the presence of metallic layers, OPGW cables exhibit high mechanical strength and are suitable for longer spans and higher tensile loads.

- ADSS Cable: ADSS cables are designed to be self-supporting and rely on their dielectric materials and aramid fibers for mechanical strength. They are ideal for shorter spans and moderate tensile loads.

- Installation and Sag:

- OPGW Cable: OPGW cables are installed using standard overhead power line installation methods and must be properly tensioned to maintain the required sag for electrical clearance.

- ADSS Cable: ADSS cables are designed to maintain a constant sag without the need for additional tensioning devices. This feature simplifies installation and reduces the risk of sag-related issues during operation.

- Weight:

- OPGW Cable: OPGW cables are generally heavier due to the presence of metal components.

- ADSS Cable: ADSS cables are lighter since they are made entirely of dielectric materials.

- Environmental Considerations:

- OPGW Cable: The metal components in OPGW cables make them susceptible to corrosion, particularly in harsh environmental conditions.

- ADSS Cable: ADSS cables are more resistant to environmental factors such as corrosion, making them well-suited for installation in challenging terrains and coastal areas.

- Ampacity:

- OPGW Cable: OPGW cables have a higher ampacity and can carry more electrical power due to their conductive core.

- ADSS Cable: ADSS cables do not carry electrical power and are solely dedicated to communication purposes.

- Cost:

- OPGW Cable: OPGW cables are generally more expensive than ADSS cables due to the inclusion of metal components and the additional functionality for power transmission.

- ADSS Cable: ADSS cables offer a cost-effective solution for communication needs and do not incur the added expense of a conductive core.

Conclusion:

Both OPGW and ADSS cables serve critical roles in power transmission and communication networks. OPGW cables excel in combining power transmission and communication functions while providing high ampacity and mechanical strength. On the other hand, ADSS cables offer lightweight, non-conductive solutions primarily dedicated to communication, with cost-effectiveness and ease of installation as key advantages. Understanding these differences allows power and communication companies to make informed decisions when choosing the most suitable cable for their specific requirements.